Analysis of Nanofluids as Cutting Fluid in Grinding EN-31 Steel

Corresponding Author: K.Manoj Kumar

Nano-Micro Letters,

Vol. 3 No. 4 (2011), Article Number: 209-214

Abstract

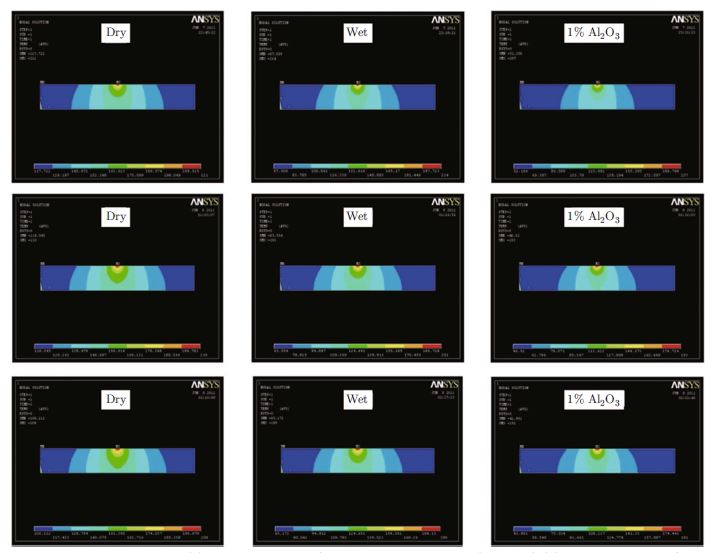

Grinding requires high specific energy which develops high temperatures at wheel work piece interface. High temperatures impair work piece quality by inducing tensile residual stress, burn, and micro cracks. Control of grinding temperature is achieved by providing effective cooling and lubrication. Conventional flood cooling is often ineffective due to enormous heat generation and improper heat dissipation. This paper deals with an investigation on using TRIM E709 emulsifier with Al2O3 nanoparticles to reduce the heat generated at grinding zone. An experimental setup has been developed for this and detailed comparison has been done with dry, TRIM E709 emulsifier and TRIM E709 emulsifier with Al2O3 nanoparticles in grinding EN-31 steel in terms of temperature distribution and surface finish. Results shows that surface roughness and heat penetration were decreased with addition of Al2O3 nanoparticles.

Keywords

Download Citation

Endnote/Zotero/Mendeley (RIS)BibTeX

- E. Brinksmeier, C. Heinzel and M. Wittmann, Annual CIRP, 48, 581 (1999). http://dx.doi.org/10.1016/S0007-8506(07)63236-3

- S. Malkin, R. B. Anderson, Trans. ASME, J. Eng. Ind. 96, 1184 (1974). http://dx.doi.org/10.1115/1.3438493

- T. D. Howes, Annual. CIRP, 39, 313(1990). http://dx.doi.org/10.1016/S0007-8506(07)61061-0

- L. R. Silva, E. C. Bianchi, R.Y. Fusse, R. E. Catai, T.V. Franca and P. R. Int. J. Machine Tools M. 47, 412 (2007). http://dx.doi.org/10.1016/j.ijmachtools.2006.03.015

- S. Shaji and V. Radhakrishan, Int. J. machine tools M. 42, 733 (2002). http://dx.doi.org/10.1016/S0890-6955(01)00158-4

- M. Alberts, K. Kalaitzidou and S. Melkote, Int. J. Machine Tools M. 49, 966 (2009). http://dx.doi.org/10.1016/j.ijmachtools.2009.06.005

- J. A. Eastman, S. R. Phillpot, S. U. S. Choi and P. Keblinski, Annu. Rev. Mater. Res. 34, 219 (2004). http://dx.doi.org/10.1146/annurev.matsci.34.052803.090621

- V. Vasu, K. R. Krishna and A. C. S. Kumar, Int. Energ. J. 8, 178 (2007).

- Z. Li, X. Feng and H. Yao, J. Mater. Sci. 39, 2267 (2004). http://dx.doi.org/10.1023/B:JMSC.0000017804.38298.92

- V. Vasu, K. R. Krishna and A. C. S. Kumar, Therm. Sci. J. 12, 27 (2008).

References

E. Brinksmeier, C. Heinzel and M. Wittmann, Annual CIRP, 48, 581 (1999). http://dx.doi.org/10.1016/S0007-8506(07)63236-3

S. Malkin, R. B. Anderson, Trans. ASME, J. Eng. Ind. 96, 1184 (1974). http://dx.doi.org/10.1115/1.3438493

T. D. Howes, Annual. CIRP, 39, 313(1990). http://dx.doi.org/10.1016/S0007-8506(07)61061-0

L. R. Silva, E. C. Bianchi, R.Y. Fusse, R. E. Catai, T.V. Franca and P. R. Int. J. Machine Tools M. 47, 412 (2007). http://dx.doi.org/10.1016/j.ijmachtools.2006.03.015

S. Shaji and V. Radhakrishan, Int. J. machine tools M. 42, 733 (2002). http://dx.doi.org/10.1016/S0890-6955(01)00158-4

M. Alberts, K. Kalaitzidou and S. Melkote, Int. J. Machine Tools M. 49, 966 (2009). http://dx.doi.org/10.1016/j.ijmachtools.2009.06.005

J. A. Eastman, S. R. Phillpot, S. U. S. Choi and P. Keblinski, Annu. Rev. Mater. Res. 34, 219 (2004). http://dx.doi.org/10.1146/annurev.matsci.34.052803.090621

V. Vasu, K. R. Krishna and A. C. S. Kumar, Int. Energ. J. 8, 178 (2007).

Z. Li, X. Feng and H. Yao, J. Mater. Sci. 39, 2267 (2004). http://dx.doi.org/10.1023/B:JMSC.0000017804.38298.92

V. Vasu, K. R. Krishna and A. C. S. Kumar, Therm. Sci. J. 12, 27 (2008).