Research on the Forming Mechanism of Micro/Nano Features during the Cast Molding Process

Corresponding Author: Yucheng Ding

Nano-Micro Letters,

Vol. 3 No. 4 (2011), Article Number: 249-255

Abstract

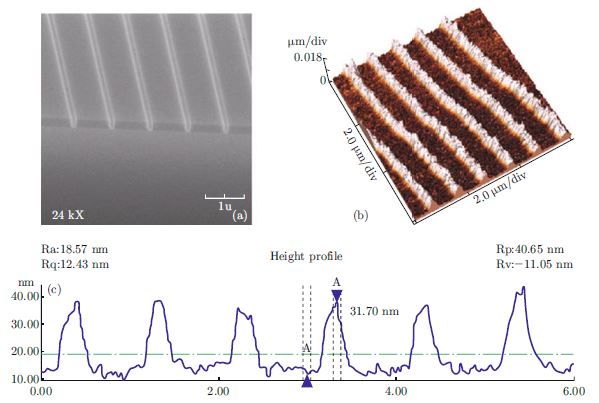

Cast molding process has provided a reliable, simple and cost-effective way to fabricate micro structures since decades ago. In order to obtain structures with fine, dense and deep nano-size features by cast molding, it is necessary to study the forming mechanism in the process. In this paper, based on major steps of cast molding, filling models of liquid are established and solved; and the forming mechanism of liquid is revealed. Moreover, the scale effect between the liquid and the cavity on the filling velocity of liquid is studied. It is also interesting to find out that the wettability of liquid on the cavity may be changed from wetting to dewetting depends on the pressure difference. Finally, we experimentally verify some of our modeling results on the flowing and filling state of the liquid during the cast molding process.

Keywords

Download Citation

Endnote/Zotero/Mendeley (RIS)BibTeX

- S. Masuda, M. Washizu and T. Nanba, IEEE Trans. Ind. Appl. 25, 732 (1989). http://dx.doi.org/10.1109/28.31255

- B. Jo and D. J. Beebe, Proc. SPIE. 3877, 222 (1999). http://dx.doi.org/10.1117/12.359340

- G. Chen, G. T. Mccandless, R. L. Mccarley and S. A. Soper, Lab Chip. 7, 1424 (2007).

- L. Gitlin, P. Schulze and D. Belder, Lab Chip. 9, 3000 (2009). http://dx.doi.org/10.1039/b904684d

- L. D. Sio, J. G. Cuennet, A. E. Vasdekis and D. Psaltis, Appl. Phys. Lett. 96, 131112 (2010). http://dx.doi.org/10.1063/1.3377801

- Y. Xia, G. M. Whitesides, Angew. Chem. Int. Ed. Engl. 37, 550 (1998). http://dx.doi.org/10.1002/(SICI)1521-3773(19980316)37:5<550::AID-ANIE550>3.0.CO;2-G

- W. M. Choi and O. O. Park, Microelectron. Eng. 70, 131 (2003). http://dx.doi.org/10.1016/S0167-9317(03)00436-2

- U. Plachetka, M. Bender, A. Fuchs, B. Vratzov, T. Glinsner, F. Lindner and H. Kurz, Microelectron. Eng. 73, 167 (2004). http://dx.doi.org/10.1016/S0167-9317(04)00093-0

- X. Ye, Y. Ding, H. Liu and Y. Duan, Thin Solid Films 581, 6933 (2010). http://dx.doi.org/10.1016/j.tsf.2010.06.038

- X. Ye, Y. Ding, Y. Duan, H. Liu and B. Lu, J. Vac. Sci. Technol. B 28, 138 (2010). http://dx.doi.org/10.1116/1.3290753

- J. Narasimhan and I. Papautsky, J. Micromech. Microeng. 14, 96 (2004). http://dx.doi.org/10.1088/0960-1317/14/1/013

- C. R. Martin and I. A. Aksay, J. Electroceramics. 12, 53 (2004).

- V. N. Goral, Y. Hsieh, O. N. Petzold, R. A. Faris and P. K. Yuen, J. Micromech. Microeng. 21, 017002 (2011). http://dx.doi.org/10.1088/0960-1317/21/1/017002

- X. Ye, Y. Ding, Y. Duan, H. Liu and J. Shao, J. Vac. Sci. Technol. B 28, 86 (2010). http://dx.doi.org/10.1116/1.3273601

- K. Ren, W. Dai, J. Zhou, J. Su and H. Wu, PNAS 17, 8162 (2011). http://dx.doi.org/10.1073/pnas.1100356108

- Y. M. Chiang, M. Bachman, C. Chu and G. P. Li, Proc. SPIE. 3877, 303 (1999). http://dx.doi.org/10.1117/12.359350

- X. Ye, H. Liu, Y. Ding, H. Li and B. Lu, Microelectron. Eng. 86, 310 (2009). http://dx.doi.org/10.1016/j.mee.2008.10.011

- S. A. Somers and H. T. Davis, J. Chem. Phys. 96, 5389 (1992). http://dx.doi.org/10.1063/1.462724

- K. P. Travis, B. D. Todd and D. J. Evans, Phys. Rev. E55, 4288 (1997). http://dx.doi.org/10.1103/PhysRevE.55.4288

- A. C. Eringen and K. Okada, Int. J. Eng. Sci. 33, 2297 (1995). http://dx.doi.org/10.1016/0020-7225(95)00071-5

References

S. Masuda, M. Washizu and T. Nanba, IEEE Trans. Ind. Appl. 25, 732 (1989). http://dx.doi.org/10.1109/28.31255

B. Jo and D. J. Beebe, Proc. SPIE. 3877, 222 (1999). http://dx.doi.org/10.1117/12.359340

G. Chen, G. T. Mccandless, R. L. Mccarley and S. A. Soper, Lab Chip. 7, 1424 (2007).

L. Gitlin, P. Schulze and D. Belder, Lab Chip. 9, 3000 (2009). http://dx.doi.org/10.1039/b904684d

L. D. Sio, J. G. Cuennet, A. E. Vasdekis and D. Psaltis, Appl. Phys. Lett. 96, 131112 (2010). http://dx.doi.org/10.1063/1.3377801

Y. Xia, G. M. Whitesides, Angew. Chem. Int. Ed. Engl. 37, 550 (1998). http://dx.doi.org/10.1002/(SICI)1521-3773(19980316)37:5<550::AID-ANIE550>3.0.CO;2-G

W. M. Choi and O. O. Park, Microelectron. Eng. 70, 131 (2003). http://dx.doi.org/10.1016/S0167-9317(03)00436-2

U. Plachetka, M. Bender, A. Fuchs, B. Vratzov, T. Glinsner, F. Lindner and H. Kurz, Microelectron. Eng. 73, 167 (2004). http://dx.doi.org/10.1016/S0167-9317(04)00093-0

X. Ye, Y. Ding, H. Liu and Y. Duan, Thin Solid Films 581, 6933 (2010). http://dx.doi.org/10.1016/j.tsf.2010.06.038

X. Ye, Y. Ding, Y. Duan, H. Liu and B. Lu, J. Vac. Sci. Technol. B 28, 138 (2010). http://dx.doi.org/10.1116/1.3290753

J. Narasimhan and I. Papautsky, J. Micromech. Microeng. 14, 96 (2004). http://dx.doi.org/10.1088/0960-1317/14/1/013

C. R. Martin and I. A. Aksay, J. Electroceramics. 12, 53 (2004).

V. N. Goral, Y. Hsieh, O. N. Petzold, R. A. Faris and P. K. Yuen, J. Micromech. Microeng. 21, 017002 (2011). http://dx.doi.org/10.1088/0960-1317/21/1/017002

X. Ye, Y. Ding, Y. Duan, H. Liu and J. Shao, J. Vac. Sci. Technol. B 28, 86 (2010). http://dx.doi.org/10.1116/1.3273601

K. Ren, W. Dai, J. Zhou, J. Su and H. Wu, PNAS 17, 8162 (2011). http://dx.doi.org/10.1073/pnas.1100356108

Y. M. Chiang, M. Bachman, C. Chu and G. P. Li, Proc. SPIE. 3877, 303 (1999). http://dx.doi.org/10.1117/12.359350

X. Ye, H. Liu, Y. Ding, H. Li and B. Lu, Microelectron. Eng. 86, 310 (2009). http://dx.doi.org/10.1016/j.mee.2008.10.011

S. A. Somers and H. T. Davis, J. Chem. Phys. 96, 5389 (1992). http://dx.doi.org/10.1063/1.462724

K. P. Travis, B. D. Todd and D. J. Evans, Phys. Rev. E55, 4288 (1997). http://dx.doi.org/10.1103/PhysRevE.55.4288

A. C. Eringen and K. Okada, Int. J. Eng. Sci. 33, 2297 (1995). http://dx.doi.org/10.1016/0020-7225(95)00071-5