Large-scale Patterning of Hydrophobic Silicon Nanostructure Arrays Fabricated by Dual Lithography and Deep Reactive Ion Etching

Corresponding Author: Chengyu Jiang

Nano-Micro Letters,

Vol. 5 No. 1 (2013), Article Number: 7-12

Abstract

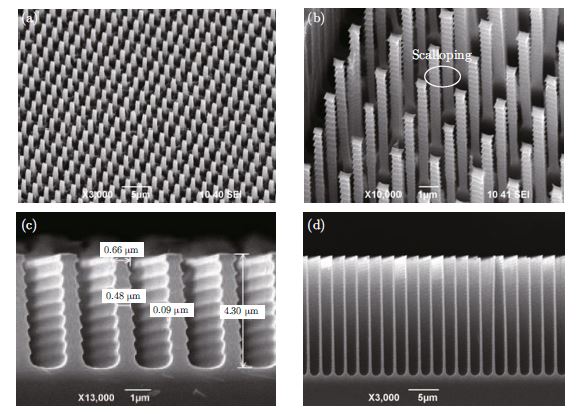

We describe a simple but efficient technique to fabricate large-scale arrays of highly ordered silicon nanostructures. By coupling dual lithography using light of 351.1 nm wavelength with deep reactive ion etching (DRIE), silicon nanostructures of excellent regularity and uniform coverage were achieved. The proposed nanofabrication method not only simplified the nanofabrication process but also produced high-aspect-ratio (higher than 15) nanostructures. The scalloping problem was also controlled by regulating DRIE parameters. The process is rapid, cheap, examined to optimize the fabrication process, and has the potential to be scaled up to large areas. The contact angle of a water droplet atop the surface is larger than 15°. Moreover, by coupling black silicon process with DRIE-based microfabrication, three-dimensional nano/nano dual-scale structures which show robust and stable hydrophobicity have been achieved. This process opens new application possibilities in optical, photoelectric, microelectronic, catalytic and biomedical applications.

Keywords

Download Citation

Endnote/Zotero/Mendeley (RIS)BibTeX

- G. Gronniger, B. Barwick and H. Batelaana, “Electron diffraction from free-standing, metal-coated transmission gratings”, Appl. Phys. Lett. 87, 124104–124106 (2005). http://dx.doi.org/10.1063/1.2053347

- A. D. Ormonde, E. C. Hicks, J. Castillo and R. P. V. Duyne, “Nanosphere lithography: Fabrication of large-area Ag nanoparticle arrays by convective self-assembly and their characterization by scanning UV-visible extinction spectroscopy”, Langmuir 201(16), 6927–6931 (2004). http://dx.doi.org/10.1021/la0494674

- Y. C. Chan, Y. K. Lee and Y. Zohar, “High-throughput design and fabrication of an integrated microsystem with high aspect-ratio sub-micron pillar arrays for free-solution micro capillary electrophoresis”, J. Micromech. Microeng. 16(4), 699–707 (2006). http://dx.doi.org/10.1088/0960-1317/16/4/005

- J. Taniguchi, K. Koga, Y. Kogo and I. Miyamoto, “Rapid and three-dimensional nanoimprint template fabrication technology using focused ion beam lithography”, Microelectron. Eng. 83(4–9), 940–943 (2006). http://dx.doi.org/10.1016/j.mee.2006.01.101

- L. J. Guo, “Nanoimprint lithography: Methods and material requirements”, Adv. Mater. 19(4), 495–513 (2007). http://dx.doi.org/10.1002/adma.200600882

- G. Sun, T. Gao, X. Zhao and H. Zhang, “Fabrication of micro/nano dual-scale structures by improved deep reactive ion etching”, J. Micromech. Microeng. 20(7), 075028 (2010). http://dx.doi.org/10.1088/0960-1317/20/7/075028

- T. M. Bloomstein, M. F. Marchant, S. Deneault, D. E. Hardy and M. Rothschild, “22-nm immersion inter-ference lithography”, Opt. Express 14(14), 6434–6443 (2006). http://dx.doi.org/10.1364/OE.14.006434

- H. H. Solak, C. David, J. Gobrecht, V. Golovkina, F. Cerrina and S. O. Kim, “Sub-50 nm period patterns with EUV interference lithography” Microelectron. Eng. 67-87, 56–62 (2003). http://dx.doi.org/10.1016/S0167-9317(03)00059-5

- C. L. Haynes and R. P. Van Duyne, “Nanosphere lithography: A versatile nanofabrication tool for studies of size-dependent nanoparticle optics”, J. Phys. Chem. B 105(24), 5599–5611 (2001). http://dx.doi.org/10.1021/jp010657m

- C. L. Cheung, R. J. Nikolić, C. E. Reinhardt and T. F. Wang, “Fabrication of nanopillars by nanosphere lithography”, Nanotechnology 17(5), 1339–1343 (2006). http://dx.doi.org/10.1088/0957-4484/17/5/028

- A. V. Whitney, B. D. Myers and R. P. Van Duyne, “Sub-100 nm triangular nanopores fabricated with the reactive ion etching variant of nanosphere lithography and angle-resolved nanosphere lithography”, Nano Lett. 4(8), 1507–1511 (2004). http://dx.doi.org/10.1021/nl049345w

- N. Nagy, E. A. Pap, E. Horv’ath, J. Volk, I. B’arsony, A. De’ak and Z. H’orvolgyi, “Large area self-assembled masking for photonic applications”, Appl. Phys. Lett. 89(6), 063104–063106 (2006). http://dx.doi.org/10.1063/1.2335668

- A. Sinitskii, S. Neumeier, J. Nelles, M. Fischer and U. Simon, “Ordered arrays of silicon pillars with controlled height and aspect ratio” Nanotechnology 18(30), 305307 (2007). http://dx.doi.org/10.1088/0957-4484/18/30/305307

- C. T. Black, K. W. Guarini, K. R. Milkove, S. M. Baker, T. P. Russell and M. T. Tuominen, “Integration of self-assembled diblock copolymers for semiconductor capacitor fabrication”, Appl. Phys. Lett. 79(3), 409–411 (2001). http://dx.doi.org/10.1063/1.1383805

- B. J. Y. Tan, C. H. Sow, T. S. Koh, K. C. Chin, A. T. S. Wee and C. K. Ong, “Fabrication of size-tunable gold nanoparticles array with nanosphere lithography, reactive ion etching, and thermal annealing”, J. Phys. Chem. B 109(22), 11100–11109 (2005). http://dx.doi.org/10.1021/jp045172n

- S. S. Mark, M. Bergkvist, P. Bhatnagar, C. Welch, A. L. Goodyear, X. Yang, E. R. Angert and C. A. Batt, “Thin film processing using S-layer proteins: Biotemplated assembly of colloidal gold etch masks for fabrication of silicon nanopillar arrays”, Colloids Surf. B 57(2), 161–173 (2007). http://dx.doi.org/10.1016/ j.colsurfb.2007.01.015

- V. Gowrishankar, N. Miller, M. D. McGehee, M. J. Misner, D. Y. Ryu, T. P. Russell, E. Drockenmuller and C. J. Hawker, “Fabrication of densely packed, well-ordered, high-aspect-ratio silicon nanopillars over large areas using block copolymer lithography”, Thin Solid Films 513(1–2), 289–294 (2006). http://dx.doi.org/ 10.1016/j.tsf.2006.01.064

- L. Sainiemi, H. Keskinen, M. Aromaa, L. Luosujarvi, K. Grigoras, T. Kotiaho, J. M. Makela and S. Franssila, “Rapid fabrication of high aspect ratio silicon nanopillars for chemical analysis”, Nanotechnology 18(50), 505303 (2007). http://dx.doi.org/10.1088/ 0957-4484/18/50/505303

- K. K. Lee, D. R. Lim, L. C. Kimerling, J. Shin and F. Cerrina, “Fabrication of ultralow-loss Si/SiO2 waveguides by roughness reduction”, Optics Lett. 26(23), 1888–1890 (2001). http://dx.doi.org/10.1364/OL. 26.001888

- D. Csontos and H. Q. Xu, “Effects of boundary roughness on the conductance of quantum wires”, Appl. Phys. Lett. 77(15), 2364–2366 (2000). http://dx.doi.org/10.1063/1.1311606

- H. Cao, Z. Yu, J. Wang, J. O. Tegenfeldt, R. H. Austin, E. Chen, W. Wu and S. Y. Chou, “Fabrication of 10 nm enclosed nanofluidic channels”, Appl. Phys. Lett. 81(1), 174–176 (2002) http://dx.doi.org/10.1063/1.1489102

- Z. Yu and S. Y. Chou, “Triangular profile imprint molds in nanograting fabrication”, Nano Lett. 4(2), 341–344 (2004). http://dx.doi.org/10.1021/ nl034947l

- P. Mukherjee, M. Kang, T. H. Zurbuchen and L. J. Guo, “Fabrication of high aspect ratio Si nanogratings with smooth sidewalls for a deep UV-blocking particle filter”, J. Vac. Sci. Technol. B 25(6), 2645–2648 (2007). http://dx.doi.org/10.1116/1.2804612

- X. F. Gao and L. Jiang, “Biophysics: Water-repellent legs of water striders”, Nature 432 (7013), 36 (2004). http://dx.doi.org/10.1038/432036a

- Y. M. Zheng, X. F. Gao and L. Jiang, “Directional adhesion of superhydrophobic butterfly wings”, Soft Matter 3(2), 178–182 (2007). http://dx.doi.org/10.1039/b612667g

- W. J. P. Barnes, “Evolution, stable heterozygosity?”, Science 318(5848), 202–203 (2007). http://dx.doi.org/10.1126/science.1150197

- Y. M. Zheng, H. Bai, Z. B. Huang, X. Tian, F. Q. Nie, Y. Zhao, J. Zhai and L. Jiang, “Directional water collection on wetted spider silk”, Nature 463 (7281), 640–643 (2010). http://dx.doi.org/10.1038/ nature08729

- C. H. Choi and C. J. Kim, “Large slip of aqueous liquid flow over a nanoengineered superhydrophobic surface”, Phys. Rev. Lett. 96(6), 066001–066004 (2006). http://dx.doi.org/10.1103/PhysRevLett.96.066001

- P. Hoyer, M. Theuer, R. Beigang and E. B. Kley, “Terahertz emission from black silicon”, Appl. Phys. Lett. 93(9), 091106–091108 (2008). http://dx.doi.org/10.1063/1.2978096

References

G. Gronniger, B. Barwick and H. Batelaana, “Electron diffraction from free-standing, metal-coated transmission gratings”, Appl. Phys. Lett. 87, 124104–124106 (2005). http://dx.doi.org/10.1063/1.2053347

A. D. Ormonde, E. C. Hicks, J. Castillo and R. P. V. Duyne, “Nanosphere lithography: Fabrication of large-area Ag nanoparticle arrays by convective self-assembly and their characterization by scanning UV-visible extinction spectroscopy”, Langmuir 201(16), 6927–6931 (2004). http://dx.doi.org/10.1021/la0494674

Y. C. Chan, Y. K. Lee and Y. Zohar, “High-throughput design and fabrication of an integrated microsystem with high aspect-ratio sub-micron pillar arrays for free-solution micro capillary electrophoresis”, J. Micromech. Microeng. 16(4), 699–707 (2006). http://dx.doi.org/10.1088/0960-1317/16/4/005

J. Taniguchi, K. Koga, Y. Kogo and I. Miyamoto, “Rapid and three-dimensional nanoimprint template fabrication technology using focused ion beam lithography”, Microelectron. Eng. 83(4–9), 940–943 (2006). http://dx.doi.org/10.1016/j.mee.2006.01.101

L. J. Guo, “Nanoimprint lithography: Methods and material requirements”, Adv. Mater. 19(4), 495–513 (2007). http://dx.doi.org/10.1002/adma.200600882

G. Sun, T. Gao, X. Zhao and H. Zhang, “Fabrication of micro/nano dual-scale structures by improved deep reactive ion etching”, J. Micromech. Microeng. 20(7), 075028 (2010). http://dx.doi.org/10.1088/0960-1317/20/7/075028

T. M. Bloomstein, M. F. Marchant, S. Deneault, D. E. Hardy and M. Rothschild, “22-nm immersion inter-ference lithography”, Opt. Express 14(14), 6434–6443 (2006). http://dx.doi.org/10.1364/OE.14.006434

H. H. Solak, C. David, J. Gobrecht, V. Golovkina, F. Cerrina and S. O. Kim, “Sub-50 nm period patterns with EUV interference lithography” Microelectron. Eng. 67-87, 56–62 (2003). http://dx.doi.org/10.1016/S0167-9317(03)00059-5

C. L. Haynes and R. P. Van Duyne, “Nanosphere lithography: A versatile nanofabrication tool for studies of size-dependent nanoparticle optics”, J. Phys. Chem. B 105(24), 5599–5611 (2001). http://dx.doi.org/10.1021/jp010657m

C. L. Cheung, R. J. Nikolić, C. E. Reinhardt and T. F. Wang, “Fabrication of nanopillars by nanosphere lithography”, Nanotechnology 17(5), 1339–1343 (2006). http://dx.doi.org/10.1088/0957-4484/17/5/028

A. V. Whitney, B. D. Myers and R. P. Van Duyne, “Sub-100 nm triangular nanopores fabricated with the reactive ion etching variant of nanosphere lithography and angle-resolved nanosphere lithography”, Nano Lett. 4(8), 1507–1511 (2004). http://dx.doi.org/10.1021/nl049345w

N. Nagy, E. A. Pap, E. Horv’ath, J. Volk, I. B’arsony, A. De’ak and Z. H’orvolgyi, “Large area self-assembled masking for photonic applications”, Appl. Phys. Lett. 89(6), 063104–063106 (2006). http://dx.doi.org/10.1063/1.2335668

A. Sinitskii, S. Neumeier, J. Nelles, M. Fischer and U. Simon, “Ordered arrays of silicon pillars with controlled height and aspect ratio” Nanotechnology 18(30), 305307 (2007). http://dx.doi.org/10.1088/0957-4484/18/30/305307

C. T. Black, K. W. Guarini, K. R. Milkove, S. M. Baker, T. P. Russell and M. T. Tuominen, “Integration of self-assembled diblock copolymers for semiconductor capacitor fabrication”, Appl. Phys. Lett. 79(3), 409–411 (2001). http://dx.doi.org/10.1063/1.1383805

B. J. Y. Tan, C. H. Sow, T. S. Koh, K. C. Chin, A. T. S. Wee and C. K. Ong, “Fabrication of size-tunable gold nanoparticles array with nanosphere lithography, reactive ion etching, and thermal annealing”, J. Phys. Chem. B 109(22), 11100–11109 (2005). http://dx.doi.org/10.1021/jp045172n

S. S. Mark, M. Bergkvist, P. Bhatnagar, C. Welch, A. L. Goodyear, X. Yang, E. R. Angert and C. A. Batt, “Thin film processing using S-layer proteins: Biotemplated assembly of colloidal gold etch masks for fabrication of silicon nanopillar arrays”, Colloids Surf. B 57(2), 161–173 (2007). http://dx.doi.org/10.1016/ j.colsurfb.2007.01.015

V. Gowrishankar, N. Miller, M. D. McGehee, M. J. Misner, D. Y. Ryu, T. P. Russell, E. Drockenmuller and C. J. Hawker, “Fabrication of densely packed, well-ordered, high-aspect-ratio silicon nanopillars over large areas using block copolymer lithography”, Thin Solid Films 513(1–2), 289–294 (2006). http://dx.doi.org/ 10.1016/j.tsf.2006.01.064

L. Sainiemi, H. Keskinen, M. Aromaa, L. Luosujarvi, K. Grigoras, T. Kotiaho, J. M. Makela and S. Franssila, “Rapid fabrication of high aspect ratio silicon nanopillars for chemical analysis”, Nanotechnology 18(50), 505303 (2007). http://dx.doi.org/10.1088/ 0957-4484/18/50/505303

K. K. Lee, D. R. Lim, L. C. Kimerling, J. Shin and F. Cerrina, “Fabrication of ultralow-loss Si/SiO2 waveguides by roughness reduction”, Optics Lett. 26(23), 1888–1890 (2001). http://dx.doi.org/10.1364/OL. 26.001888

D. Csontos and H. Q. Xu, “Effects of boundary roughness on the conductance of quantum wires”, Appl. Phys. Lett. 77(15), 2364–2366 (2000). http://dx.doi.org/10.1063/1.1311606

H. Cao, Z. Yu, J. Wang, J. O. Tegenfeldt, R. H. Austin, E. Chen, W. Wu and S. Y. Chou, “Fabrication of 10 nm enclosed nanofluidic channels”, Appl. Phys. Lett. 81(1), 174–176 (2002) http://dx.doi.org/10.1063/1.1489102

Z. Yu and S. Y. Chou, “Triangular profile imprint molds in nanograting fabrication”, Nano Lett. 4(2), 341–344 (2004). http://dx.doi.org/10.1021/ nl034947l

P. Mukherjee, M. Kang, T. H. Zurbuchen and L. J. Guo, “Fabrication of high aspect ratio Si nanogratings with smooth sidewalls for a deep UV-blocking particle filter”, J. Vac. Sci. Technol. B 25(6), 2645–2648 (2007). http://dx.doi.org/10.1116/1.2804612

X. F. Gao and L. Jiang, “Biophysics: Water-repellent legs of water striders”, Nature 432 (7013), 36 (2004). http://dx.doi.org/10.1038/432036a

Y. M. Zheng, X. F. Gao and L. Jiang, “Directional adhesion of superhydrophobic butterfly wings”, Soft Matter 3(2), 178–182 (2007). http://dx.doi.org/10.1039/b612667g

W. J. P. Barnes, “Evolution, stable heterozygosity?”, Science 318(5848), 202–203 (2007). http://dx.doi.org/10.1126/science.1150197

Y. M. Zheng, H. Bai, Z. B. Huang, X. Tian, F. Q. Nie, Y. Zhao, J. Zhai and L. Jiang, “Directional water collection on wetted spider silk”, Nature 463 (7281), 640–643 (2010). http://dx.doi.org/10.1038/ nature08729

C. H. Choi and C. J. Kim, “Large slip of aqueous liquid flow over a nanoengineered superhydrophobic surface”, Phys. Rev. Lett. 96(6), 066001–066004 (2006). http://dx.doi.org/10.1103/PhysRevLett.96.066001

P. Hoyer, M. Theuer, R. Beigang and E. B. Kley, “Terahertz emission from black silicon”, Appl. Phys. Lett. 93(9), 091106–091108 (2008). http://dx.doi.org/10.1063/1.2978096